- NetSuite Wholesale Distribution, Wholesale Distribution - Solutions

Efficient warehouse management is more than just an operational necessity in today’s fast-paced world, it’s a competitive advantage. However, knowing when your current warehouse management system is falling short can be challenging. Often, what might seem like a minor inconvenience could be a significant bottleneck, impacting everyday warehouse operations and your overall business performance. Understanding the difference between small issues and critical deficiencies is crucial for maintaining an efficient warehouse.

In this blog, we have explored some common problems associated with basic warehouse management systems that could be impacting the success of your business. While on its own each of these issues may seem unimportant, together they can significantly influence operations. By identifying these 10 signs, you can make an informed decision about upgrading to a more sophisticated warehouse management system (WMS) that not only meets your current demands but also supports future growth.

1. No Multi-Location Inventory Tracking

As businesses grow and expand, they typically require more than one location, whether it’s stores, warehouses or third-party facilities. This is when the limitations of entry-level inventory management systems become more apparent. These systems are typically designed for single-location operations, meaning they struggle to track inventory across multiple locations, resulting in a lack of insight. This can complicate order fulfilment processes and increase costs by not allowing for the optimisation of shipping routes or inventory pulling. Not to mention, it can hinder purchasing decisions. Without clear visibility into stock levels, ordering and allocating stock can become a guessing game, making the process more complicated.

2. Manual Updates to Product Records

Typically, basic warehouse management systems will store product details, yet they often need to provide more key information, such as item location by zone or special handling instructions. When your e-commerce and POS systems aren’t integrated with your inventory systems, significant manual effort is required to update product information across multiple platforms too, increasing the likelihood of human error. This seemingly minor inconvenience can lead to hours of wasted time each week manually updating and checking inventory records. Upgrading your software system can centralise information for every SKU, reduce mundane and error-prone tasks, and deliver an impressive ROI.

3. Messy Demand Planning

Effective warehouse management requires more than just current inventory visibility, you need insights into past SKU performance, seasonal trends and demand fluctuations to replenish stock. Starter systems may offer basic sales and inventory reports, but these often need to be manually uploaded into spreadsheets and it quickly becomes a messy, time-consuming process. As businesses grow and operations become more complex, the need for sophisticated demand planning increases. When sales and purchase orders increase, any mistakes will be magnified and it becomes even more important to have software you can rely on. Advanced WMS will provide you with reliable and accurate data, minimising the risk and impact of errors.

4. Painful Inventory Counts

Inventory counts are a necessary but time-consuming task, often requiring businesses to shut operations down once or twice a year. Without an effective warehouse management system, these counts are even more disruptive as they tend to involve stopping all inventory movement. Relying on spreadsheets for tracking expected quantities not only slows the process but also increases the likelihood of errors, such as double-counting items. Not to mention, without the right software, you can’t use handheld scanners that make inventory counts much easier, faster and more accurate. Similarly, cycle counts which can streamline full counts or prevent the need for them altogether, can take longer than should when you have a manual system.

5. Lack of Traceability

In highly regulated industries where recalls aren’t uncommon, being able to track every item sold is essential. You need to be able to trace products back to suppliers and the raw materials used to make them, and also trace them forward after they are sold to the customer so you can notify them of any product issues. Without a software system to automate tracking, the process can get very confusing and any inaccuracies can risk customer safety and brand reputation. A robust inventory management system can simplify traceability by automatically generating and assigning lot numbers to production runs, enabling you to keep precise records and easily reach customers if any issues arise, reducing costs and improving customer satisfaction.

6. Lack of Integration

A WMS system that lacks integration with essential business processes, such as accounting or sales, can create significant inefficiencies. Without integration, for instance, accounting teams can struggle to reconcile inventory accurately, leading to financial reporting discrepancies and it will be harder for sales teams to access real-time inventory data, resulting in errors in order processing. Similarly, without CRM integration, customer service representatives may lack visibility into customer histories or preferences, impacting service quality. These integration gaps often result in fragmented information across different systems, making it almost impossible to get a comprehensive overview of business operations and performance.

7. Difficulty in Forecasting

When your current system fails to forecast demand or capture seasonal trends accurately, it causes several challenges, including the risk of stockouts or overstock situations that don’t align with actual customer demand. Inaccurate and unreliable forecasting often results in lost sales opportunities and dissatisfied customers, as well as inventory tying up capital and space. Difficulty forecasting can disrupt supply chain operations, inventory planning and pricing strategies too, preventing you from being able to take advantage of anticipated demand. Ultimately, the inability to generate accurate demand forecasts and understand seasonal trends negatively impacts operational efficiency, profitability and customer satisfaction.

8. Poor Reporting and Analytics

Inadequate reporting capabilities and a lack of actionable insights from current warehouse management systems can restrict your ability to make informed and strategic decisions. Without visibility into critical performance metrics like inventory turnover rates and sales trends, it’s difficult to identify and correct inefficiencies. Additionally, not having reliable data prevents you from being able to develop effective pricing strategies that consider demand trends, competitor pricing and product profitability, leading to missed opportunities for maximising revenue. Not to mention, poor reporting limits the ability to assess supplier performance, making it difficult to address issues and negotiate favourable terms.

9. Over Stocking

Excess inventory that’s taking up valuable space in your warehouse and tying up capital is a clear sign that your software system isn’t working as effectively as it should be or providing the insights you need. Excessive inventory levels can lead to increased warehousing costs and reduce the available space for high-demand items, impacting overall warehouse productivity. This inefficiency not only impacts operational expenses but also restricts cash flow, preventing your ability to invest in growth initiatives. Excessive stock also increases the risk of stock obsolescence or depreciation, as products become outdated or sustain damage over time, leading to lower turnover rates that negatively affect profitability and liquidity.

10. Customer Experience

When your current WMS leads to poor customer experiences, such as delayed shipments, out-of-stock items or inaccurate order fulfilment, it sets off a chain reaction that impacts your reputation and bottom line. Delayed deliveries and unavailable products can be frustrating for customers, potentially driving them towards competitors who can meet their needs. Inaccurate fulfilment can cause further damage by undermining your competence. These days, negative experiences are often shared through word-of-mouth or online reviews, damaging your reputation and deterring prospective customers. Ultimately, these issues result in an immediate loss of sales, as well as long-term damage to your brand’s competitive standing in the market.

Upgrading Your Warehouse Management System in Ireland

All in all, replacing your old warehouse management system is key to addressing current inefficiencies and supporting business success. A new cloud-based WMS solution can transform your warehouse operations and provide you with the comprehensive tools you need for inventory management, supply chain management, logistics processes and much more.

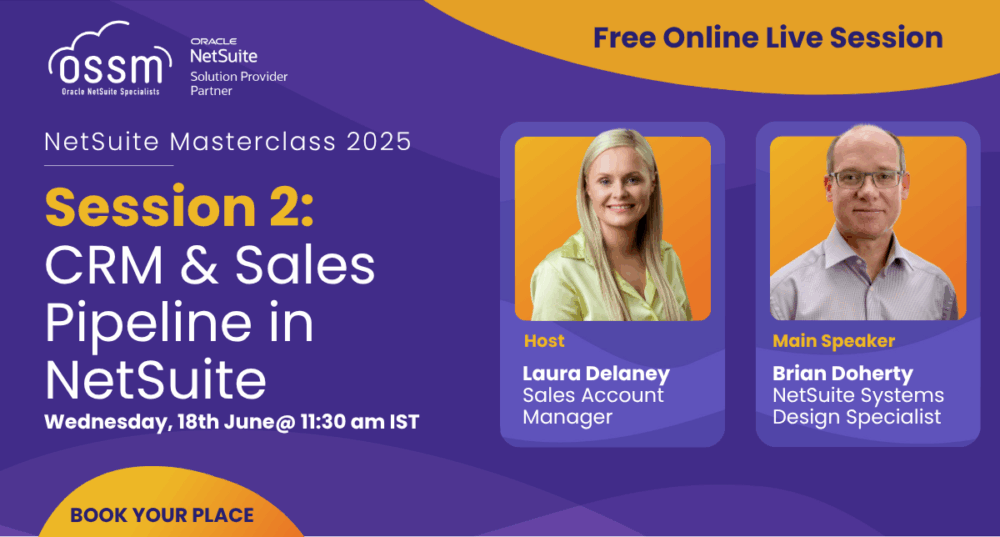

Here at OSSM, we are a dedicated NetSuite Solution Provider, and we can help you streamline your business with the right warehouse management system software. We have experience across various sectors, including distribution, manufacturing and field services, and our team will make your NetSuite journey as hassle-free as possible. We can help you integrate the right software into your warehouse operations and we will support you through the entire process, ensuring a quick and cost-effective transition. You can trust you will be in very capable hands when you turn to us for assistance with managing all aspects of your warehouse.

Why not explore our NetSuite Guide?

Download our guide: Where Warehouse Management and Finance Collide, where we have explored some common problems associated with basic warehouse management systems.

About the Author

Naren Sompalli

Naren holds a Bachelor of Engineering degree from BNM Institute of Technology. As a NetSuite specialist, he is involved in implementation at OSSM, collaborating with a team of experienced consultants. Naren conducts workshops for solution implementation and delivery, providing technical support and expertise.